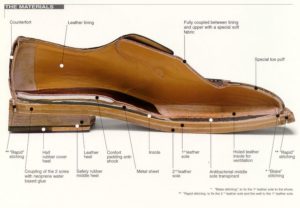

Shoe Construction: Anatomy of a Shoe

Ever wondered what goes inside your bespoke shoes? With this post, we hope to de-construct the anatomy of the shoe and explain the shoemaking process, to showcase the intricate details & individual parts it takes to complete a premium handmade shoe.

Since the 19th century, handmade shoe construction has hardly changed. Luxury handmade shoes are made out of a number of high quality materials to construct an overall product that is built to last and guarantees years of satisfaction for the owners.

It takes more than 30 individual parts to construct a luxury handmade shoe. ‘Construction’ is an appropriate term because over the course of the shoemaking process, the shoemaker will fit one part into another, adjusting them over or below each other, thus hand crafting and building the flat surface of the leather of the upper into a three dimensional shape. Once the leather for the soles and other parts of the lower section of the shoe is placed on the shoemaker’s bench, together with the made-to-measure last and the parts of the upper that have been sewn together, it is now time for the shoemaker to begin the first few operations in constructing the bespoke shoe.

Cork filing

Cork filling in the hollow area created by the filling of the welt gives the sole a certain springiness and stability as the wearer walks.

Counter

The inside counter is a piece of leather fitted to the place where the two parts of the upper are joined as a reinforcement, and acts as an extension of the heel, holding the foot firmly in the shoe. The outside counter is cut from the leather of the uppers and covers the outside of the stitched sides. It can be either quite a narrow strip or a larger piece of leather matching the shape of the heel.

Heel Lifts

The heel is made from two to four pieces of stout leather, known as lifts.

Heel top Piece

The outer section of leather on the heel, which comes into direct contact with the ground.

Inside Toe Cap

A piece of leather one-sixteenth of an inch (1.7-2 mm) thick is cut from the neck area of the hide. Its shape will depend on the model of the shoe, and it is fitted between the leather of the upper and the lining. The inside toe cap gives the toe of the shoe an attractive shape and good support, so that it will not be stretched out of shape by walking or wet weather. It also protects the toes.

Insole

The insole is a piece of leather about one-eighth of an inch (2.5 – 3.5 mm) thick (depending on the sturdiness of the shoe) on which the shoe is constructed. It is usually covered inside the shoe with a thin leather lining (the insole cover).

Insole Cover

This is a soft leather covering fitted over the insole and coming into direct contact with the foot. It may cover the entire length of the insole, three-quarters of it, or only a quarter (under the heel), as the customer wishes.

Lining

The inside of the upper is lined with pit-tanned leather. This lining comes into direct contact with the foot and must therefore be particularly supple and able to “breathe”.

Outsole

The part of the shoe that comes into direct contact with the ground. In elegant, lightweight shoes it is about three-sixteenths of an inch (5mm) thick, and correspondingly thicker in stouter shoes.

Rand

The rand is a strip of leather three-quarters of an inch [2 cm] wide and one-eighth of an inch [3 mm] thick nailed to the insole and outsole, either supplementing the welt as the basis for the outsole, or forming the foundation of the heel. In welted shoes, the rand is fastened with wooden pegs; in double-stitched shoes it is sewn into place.

Rubber heel piece

A hard, slip-proof rubber piece about a quarter inch [6 mm] thick is fitted to the heel top piece.

Shank Spring

The shank spring is a steel spring about 4 inches [10 cm] long and a half inch [1.5 cm] wide, fitted into the hallow space between the welt and the insole, and reaching from about halfway along the heel to the beginning of the ball of the foot (this part of the sole is known as the shank or sometimes the waist). It is shaped to fit the curve of the sole. The shank spring stabilizes the foot as the wearer of the shoe walks, and prevents the heel from wobbling.

Side Reinforcements

Side reinforcements are cut from the material of the upper, and fitted to the upper between the outer layer and the leather lining, and between the toe cap and the counter. They are narrow strips of leather that prevent the upper from stretching out of shape, and give good support to both sides of the shoe.

Shoe Upper

The shoemaker uses chrome-tanned, or chrome-free leather used to make the shaft of the shoe, or the outside of the upper part of the shoe. Usually using premium calfskin from the finest tanneries in Italy. The upper is usually 1.2 millimetres thick.

Welt

The strip of leather, on average 2 feet long, three-quarters of an inch wide, and an eighth of an inch thick [60 cm x 2 cm x 3 mm], is the supporting structure of the shoe. It holds the upper, insole, and sole together.