Types of Leather & Shoe Material

Maybe you want to launch your own shoe brand. Perhaps you’re thinking about buying a pair of bespoke shoes made just for you. Whichever it is, it’s imperative that you pick the perfect material for your shoe or range to be manufactured from. The types of leather, shoe material that you choose will ultimately speak volumes about your footwear or your brand. Whether you’re a designer or you want us to craft your shoes, let’s find out how to specify the material you want.

What is the best material for shoes?

There are a number of commonly used fabrics in shoemaking. Each have their own uses and the material chosen depends greatly on the type of shoe. Canvas won’t work for a dress shoe and full grain leather is probably not the best choice for a sneaker. So where do you start when your shoemaker offers you a choice of leather, textiles, foam, rubber and even plastic?

The answer to the question of ‘what is the best material for shoes?’ is, simply, there isn’t one. However if you’re looking for quality, durability and timeless style, leather is often your best choice. But here’s where it can get tricky. If you thought leather was just leather – think again. There are many different types of leather – not to mention the differences in quality, finish, color and grain. What you pick will depend on the finished look you want, plus the performance of the shoe or boot.

Your guide to selecting shoe leather

If this all feels a little bit mind-boggling, don’t worry. That’s why Italian Shoe Factory have put this guide together. Plus when we create your shoes or help you launch your private label shoe brand, we help you select the right leather material. This is also where the design brief comes in handy. This outlines the shoe you want and helps us help you make the right decision when choosing types of leather. But even with us by your side to make an informed choice it will help if you know how to identify shoe leathers. But first – a short history lesson!

Leather: A brief history

Of course we all know that shoemaking is one of the oldest trades in the world. Our primitive ancestors wore pieces of leather or cloth wrapped around their feet for protection. Our modern athletes wear high tech, high performance sneakers. It’s fair to say that shoes have changed a lot. The leather industry itself has been around for hundreds of years and has developed over time too. Tanning is an extremely skilled job and an integral part of shoemaking. As an industry it now benefits from numerous technological advances that weren’t dreamed of pre-Industrial Revolution.

The ancient Egyptians, Greeks, Mesopotamians, Chinese and Indians had already developed a number of different tanning processes. But these days, leather production is far more efficient, hygienic and, crucially, environmentally friendly and sustainable. And sustainability is key. The Global Leather Goods Market 2017-2021 Report states the leather market has a potential to grow at a compound annual rate of nearly 5% by 2021. In fact, the total market value in 2017 was $217.49 billion. By 2021, it’s anticipated to be $271.21 billion.

Where does leather come from?

Back to the topic. Most of us know that for types of leather, shoe material comes from animals. But if you’re wondering ‘where does leather come from?’ – as in really come from – read on. The most commonly used leather material for goods – including shoes – is cow leather. This is favored thanks to its flexibility, stretchability and durability. All crucial components when creating high quality leather footwear. Genuine leather from cows also comes in a range of colors, grades and styles – and prices too. But cows aren’t the only animals used for leather: calf leather is also popular, thanks to its softness. You’ll also find leather for shoes from goats, pigs and sheep, and from more ‘exotic’ creatures like alligators, ostriches and kangaroos.

For the sake of this article, we’ll focus on the cow. But not all cows are alike and different breeds produce different quality hides. This can be down to factors such as their genetics and even their environment. For example, a cow in a tropical climate is far more likely to be plagued by insects which will bite it often leaving scars. Meanwhile cows reared in colder climates are more likely to have thicker skin or hair for protection against the elements.

Types of leather: Shoe material low down

One thing that is important to know when selecting types of leather, shoe material is the type of grain. The hide of a cow is thick and is made up of two distinct parts. The top surface, or the animal’s outer skin, is what we call the ‘grain’. This determines the value of the hide. Ideally the fibres and surface of this part of the leather will be firm, smooth, tight and dense. Further down, deeper into the hide the fibers will become softer and looser. The term for these layers is the split although it can also be known as split leather, suede or split suede. The name is derived from the large metal blade used to split the top grain from the suede surface.

So we now know where does leather come from – and now you’ll want to know how to identify shoe leathers. Here we’re going to take a look at four different types of leather.

Full grain leather

The highest quality leather, and therefore the most expensive, full grain leather is sourced from the hide’s top layer. It comprises of the grain – hence the name. Known for its durability, full grain leather can present challenges for the craftsman. However its ability to absorb body oils means the leather ages well, adopting a worn-in patina that makes it unique to the wearer.

Top grain leather

With more flexibility and a smoothness that full grain leather doesn’t quite possess, top grain leather nonetheless ranks second. Enhanced by dying or staining, it doesn’t rank quite as highly as full grain thanks to its tendency to stretch over time. It is, however, long lasting and strong. Top grain leather is usually created by splitting the top layer of the skin to remove any blemishes. It will then be sanded to smooth away any of these remaining natural imperfections.

Corrected grain leather

Also referred to as bottom cut or split leather, corrected grain is most commonly referred to as genuine leather. It is obtained by taking the layers of skin that are left after the top is split away.

Like top grain leather, it will be sanded to remove any of the natural blemishes that occur in the hide and it is often embossed or spray painted. This gives the leather a more natural looking finish that belies corrected grain’s tougher texture. On the flip side, it also changes the leather’s natural ability to ‘breathe’.

Bonded leather

As the name hints, bonded leather is made using the hide’s leftover pieces which are bonded together using latex or polyurethane with a fibre sheet base. No inch of the hide is wasted, with even the shavings being used to create fabric. Like corrected grain leather, bonded leather is often spray painted to give it an appearance more akin to top or full grain leather.

Most manufacturers won’t tell you what percent of natural leather is used in bonded leather goods. Not surprisingly, this is the lowest, and cheapest, grade of leather.

How Leather Is Made: Tanning Process

The types of leather used to make footwear start life as animal hide. This needs to be processed and it is during this stage that the hair is extracted from the top surface. Meanwhile, any leftover fat and flesh is removed from the hide’s inner. After this the hide will be tanned. The object of tanning is to preserve the fibres of the leather, and coloring, oil and preservatives will be added. Fat may also be introduced to make the leather softer and more pliable. But this process alone is not enough to create leather material that withstands the wear and tear that footwear demands. Enter tanning, which changes the protein structure of the hide to make it stronger and more durable.

There is more than one way to tan leather for shoes with either mineral or vegetable processes being adopted among several other leather tanning practices. Tanners might find themselves rather damp by the end of a day’s work: Their job involves tumbling the hides in huge vats full of water, dyes and chemicals. High quality genuine leather isn’t created in a few minutes either as this particular process can take more than 10 hours. Essentially, tanning converts the protein of the rawhide into a durable material. The most common tanning processes include mineral or chrome tanning, vegetable tanning, and glutaraldehyde tanning.

Vegetable Tanning:

Vegetable tanning has been around for thousands of years. Unlike mineral tanning, it uses a naturally occurring polyphenol astringent chemical called tannin. This is usually found in bark, leaves, and branches of trees such as oak, chestnut, or mimosa. However, the process is time-consuming, laborious, and expensive. There are two types of vegetable tanning processes. The slow process takes about 30 days, while the rapid tanning process only lasts about 36 to 48 hours.

Mineral or Chrome Tanning

Mineral or chrome tanning is the most popular tanning process because it’s much quicker, affordable, and less labor intensive than the others. In 1858, it was introduced as an alternative to the expensive and time-consuming vegetable tanning process. The process can be automated and lasts a day at most. Usually, the time for chromium tanning is around 2 or 3 hours for small and thin skins. However, the chrome tanning process creates a negative environmental impact as it comprises heavy usage of acids and other chemicals. The toxic waste can seep into groundwater and contaminate drinking water supplies. The resulting environmental implications are a major concern, especially in developing countries.

At Italian Shoe Factory we believe in sustainable shoe production. You can read about our commitment to more sustainable tanning processes , where we outline the intricate steps involved in the leather treatment process.

Sustainability and Ethics

We touched upon sustainable shoe production earlier and we thought it’d be nice to finish on this topic. Sustainable fashion is big news for F/W 2019 and designers and customers are exploring ways of embracing a greener lifestyle. With more and more people adopting veganism, at Italian Shoe Factory we also offer vegan leather as an option. After all, we know that it is perfectly possible to be a fashion AND animal lover at the same time! Whether you’re a sneakerhead wanting to manufacture your own sports shoes or you’re intrigued by vegan leather shoes, contact us.

We touched upon sustainable shoe production earlier and we thought it’d be nice to finish on this topic. Sustainable fashion is big news for F/W 2019 and designers and customers are exploring ways of embracing a greener lifestyle. With more and more people adopting veganism, at Italian Shoe Factory we also offer vegan leather as an option. After all, we know that it is perfectly possible to be a fashion AND animal lover at the same time! Whether you’re a sneakerhead wanting to manufacture your own sports shoes or you’re intrigued by vegan leather shoes, contact us.

Vegan Leather

Vegan leather and faux leather are just two different names for the same material. It means that no animal skins were used in the fabrication of the leather. The majority of vegan leather bags and shoes are made from polyurethane which is a polymer fabric (also known as PU leather or faux leather). But what does vegan leather actually look like? Is it any good? And will people know whether or not you’re wearing real or faux leather? You can deep dive to learn more about vegan leather in our what is vegan leather post.

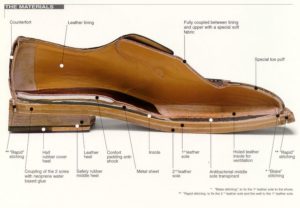

How many materials are in a pair of shoe?

We’ve learned how to identify types of leather, shoe material but what about the end product? The shoes themselves? You’ve asked where does leather come from but have you wondered what’s inside a women’s high heel shoe? Or how many materials are in a pair of sneakers? If you’ve a burning curiosity for all things footwear, it’s possible these are questions that have played on your mind!

Your average piece of footwear is made up from a number of textiles. And probably none more so than a pair of sneakers. A lot goes into making sports shoes and they can consist of any combination of man-made polymer fibers. These include nylon or polyester, Lycra, cotton canvas, synthetic leather or PU leather. Man-made textiles are normally made from two layers: a woven / non-woven polyester fiber backing layer plus a processed outer surface.

Your average piece of footwear is made up from a number of textiles. And probably none more so than a pair of sneakers. A lot goes into making sports shoes and they can consist of any combination of man-made polymer fibers. These include nylon or polyester, Lycra, cotton canvas, synthetic leather or PU leather. Man-made textiles are normally made from two layers: a woven / non-woven polyester fiber backing layer plus a processed outer surface.

Of course, high-end fashion sneakers made from leather are also popular, although it’s not recommended you run a marathon in them! Leather sneakers are usually given a water-resistant microfiber PU backing which has a smooth, clean cut surface. This can also be dyed, making it perfect for trend-led casual footwear. Thinking about starting your own sneaker brand? Talk to Italian Shoe Factory today – we don’t just create formal footwear!

In Conclusion

By now, we hope this comprehensive guide will address all your concerns from understanding leather grades and manufacturing processes to identifying the right genuine leather for your products. Choosing genuine leather is a given when it comes to handmade high quality shoes. Because it’s a natural material, no two pieces are the same and the character will change as it is worn.

And because of the high quality leather used to make Italian Shoe Factory shoes, they should be lovingly cared for. We treat our shoes with the utmost respect during the manufacturing process. And we know our customers who appreciate the craftsmanship and fine materials do the same. We hope you get many happy years from your bespoke leather shoes too! Tell us about your experience with leather, we encourage you to share your experiences in the comments section below.