How to Get a Handbag Prototype Made

If you’ve ever dreamed of creating your own handbag line, the first step is to get a prototype made. A handbag prototype not only helps you visualize your design but also allows you to test its functionality and assess the overall quality. In this guide, we’ll walk you through the process of getting a handbag prototype made, from finding the right manufacturer to choosing materials and refining your design. Whether you’re a budding fashion entrepreneur or a passionate handbag enthusiast, this guide will provide valuable insights to bring your handbag vision to life.

In this article, we’ll discuss how partnering with an experienced leather factory can greatly benefit your project, as well as guide you through the process of finding the perfect leather goods manufacturer to meet your needs.

Finding the Right Prototype Manufacturer:

It’s crucial to select a leather goods supplier who understands your goals and can deliver high-quality results. There is a wide range of leather factories with different specializations, such as private label handbags, all-purpose leather products manufacturers, or even niche leather goods makers specializing in luxury or eco-friendly items. When choosing a factory or a leather goods maker near me, you’ll want to consider their experience, reputation, and access to resources specific to your industry, whether that’s the fashion world, luxury goods, or sustainable products.

Launching a successful leather goods business requires investment not only in your designs but also in your partnerships. Working with a private label leather goods manufacturer has many benefits including streamlined production, brand consistency, and potential cost savings. By relying on their expertise, you can focus on other aspects of your business, like marketing and customer retention, and let the leather products manufacturers handle the intricacies of producing your dream handbag prototype.

Not sure how to share your designs with a manufacturer?

The first step after you have identified the right manufacturer is to prepare a handbag Tech Pack/Spec Sheet.

Download the Italian Shoe Factory Tech Pack guide & template, which includes a PDF guide along with adobe illustrator templates for footwear and handbags that you can follow easily.

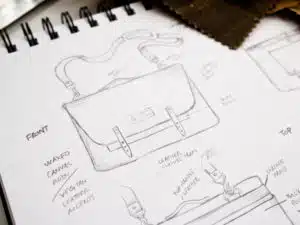

A typical leather goods tech pack may include the shape, structure, materials to be used, grading, colorway, sizes, labels etc.

A clear Tech Pack also helps in getting a quote for your prototype sample and production orders as per quantity requirement. Some of the items that a Tech Pack may include:

- Bag design details and materials to be used for each component of the handbag

- Color specifications and pantone number for each component

- Image references of hardware or any jewelry accessories

- Placement and style of brand labels within the leather goods.

- Box Packaging and branding details

Understanding Handbag Prototype Process:

Italian Shoe Factory stands out as a leading leather bag factory with decades of expertise in the leather goods industry. As a top leather goods supplier, they boast a deep understanding of various leather types, making them the ideal partner for your handbag manufacturing needs.

Working with a reputable leather goods maker like Italian Shoe Factory has numerous benefits. They offer a wide range of services, including designing private label leather bags and ensuring high-quality craftsmanship across all products. Moreover, their handbag manufacturers are skilled in creating the perfect prototype for your leather goods business.

Here is the step-by-step guide to our private label leather goods/handbag prototyping process:

- Technical Consultation: The process begins with a comprehensive technical consultation. During this stage, detailed discussions on the handbag’s design, functionality, and aesthetic appeal take place. Designers, manufacturers, and the client collaborate closely to ensure all parties have a clear understanding of the product vision and requirements.

- Material Sourcing: Once the design details are ironed out, the next step involves sourcing the materials needed for the handbag. This includes identifying the right quality and type of leather, lining materials, and any other fabrics or elements needed. The sourcing process should focus on quality, durability, and sustainability.

- 2D Pattern Making: The next stage is the creation of a 2D pattern for the handbag. This pattern serves as a blueprint for the manufacturing process. It outlines the exact dimensions, cut-outs, stitching lines, and other design elements of the bag.

- Bag Dies Development: After the pattern is finalized, bag dies are developed. These are essentially templates or cutting tools that ensure each component of the bag is cut precisely for assembly. This ensures that each manufactured handbag is consistent in size and shape.

- Component Sourcing: Apart from the leather and other fabric materials, a handbag also requires various components like zippers, buckles, handles, straps, clasps, etc. These components need to be sourced from trusted suppliers to ensure they match the overall quality and aesthetic of the bag.

- Procurement of Hardware Elements and Embellishments: The final step in the prototyping process involves sourcing any hardware elements and embellishments that the design may require. This could range from metal studs and decorative elements to brand logos and other identifying marks.

Remember, each of these steps is crucial in the creation of a high-quality, market-ready leather handbag. Details matter in manufacturing, and each process contributes to the overall product.

Materials and Costs Involved

When it comes to getting a handbag prototype made, working with the Italian Shoe Factory is a top choice. As a renowned leather goods manufacturer, they are the best choice for producing top-quality handbags at affordable costs. With a broad range of materials and a skilled workforce, they’ve established themselves as a prime option for anyone in the leather goods industry.

One of the key factors in creating a handbag prototype is the choice of materials. The Italian Shoe Factory is known for their expertise as a leather factory and leather goods supplier, delivering high-quality leather products to customers around the world. They source the finest leather for their projects, ensuring that every handbag created is of premium quality.

Some materials used in the production process include:

- Full-grain leather

- Top-grain leather

- Patent leather

- Faux leather

- Vegan leather

We understand that costs play a significant role in decision-making. By working with a reliable leather goods maker like the Italian Shoe Factory, you’ll find competitive prices that cater to a wide range of budgets. Besides offering fair prices as a leather bag factory, they also provide the convenience of private label handbags for those looking to start or expand their leather goods business.

While we charge a lump-sum prototyping fee, here’s a breakdown of costs involved in the handbag prototype process which is completely be based on the complexity of design:

| Item | Cost Range |

| Material Costs | $50-$250+ |

| Labor Costs | $100-$500+ |

| Pattern Making | $100-$300+ |

| Prototype Development | $300-$1,500+ |

As a leading leather goods company, the Italian Shoe Factory ensures that their clients’ needs are met by offering a variety of services. These include private label leather bags and private label leather goods for those who are looking to create a brand identity. Rest assured, you’re in good hands when working with leather goods manufacturers who prioritize delivering quality work.

In conclusion, getting a handbag prototype made with the Italian Shoe Factory guarantees a top-quality product at a reasonable cost. So, whether you’re a seasoned leather goods industry professional or just starting your leather goods business, partnering with the Italian Shoe Factory as your leather goods maker near me is a wise choice. With their expertise and exceptional materials, you can trust them to create a handbag that represents your vision perfectly.

Conclusion

Finding the right leather bag factory is vital in creating a successful handbag prototype, and ultimately establishing a thriving leather goods business. Among the various leather goods manufacturers, choosing the Italian Shoe Factory stands out in the leather goods industry. Their expertise in leather goods manufacturing sets them apart from other factories and suppliers.

As a renowned leather goods company, Italian Shoe Factory excels in leather manufacturing, offering both private label handbags and private label leather goods. They cater to designing leather products specifically tailored to individual brands and businesses. Their commitment to quality and craftsmanship is crucial for those looking to enter the highly competitive leather goods market.

The advantages of working with Italian Shoe Factory include:

- Vast experience as a leather goods maker

- Comprehensive range of leather products offered

- Collaborating with highly skilled leather bag manufacturers

- Diverse leather manufacturing capabilities

- Impeccable reputation in the leather goods business

Partnering with a reputable leather goods supplier like Italian Shoe Factory makes it easier to bring your vision to life. They offer transparent communication and customer service throughout the production process. Moreover, their flexible approach allows for private label leather bags and leather goods customization, addressing the specific needs of your business.

For those looking for a “leather goods maker near me,” the Italian Shoe Factory is at the forefront of the leather goods industry – an ideal choice for handbag manufacturers and private label leather goods. In conclusion, entrusting your leather goods project to them ensures exceptional quality, attention to detail, and unwavering dedication to your success.